Sweet Maple Sugar

Every year, maple sap runs for six to twelve weeks between February and April. For an extended period the temperature rises above freezing in the daytime and falls below freezing at night. This freeze-thaw cycle is necessary to make maple sugar and is unique to the Great Lakes region and east towards the Atlantic Ocean.

Indigenous peoples have been collecting maple sap for so long ago that we cannot pinpoint exactly when they started. When European settlers arrived in North America, the settlers learned Indigenous methods for processing sap into maple sugar. Over time the process evolved to make use of new materials and changing technologies. Before modern canning and refrigeration, maple sugar was a more common product than maple syrup.

There is a long history of maple sugaring in Lambton County. Samuel Smith was an early surveyor in Brooke, Euphemia, and Zone townships. He kept a diary with detailed survey notes. On May 28, 1821, he wrote that he camped overnight at an Indigenous sugar camp.

The Lambton Heritage Museum collection includes items used to harvest and process maple sap. A tree is tapped to collect its sap by making a cut through the bark into the sapwood. A tool called a spile directs the running sap into a container. The Anishinaabe traditionally used a piece of flat cedar to guide the sap into a waiting container. Spiles were also made of carved wood or metal.

The earliest containers were made of birchbark. Later containers were pails made of wood slats held together with metal hoops, flat metal pans, or metal pails. The Howes family had a sugarbush in present day Dawn-Euphemia. They placed flat pans on the ground below spiles to collect sap. In the 1940s they replaced the flat pans with larger tin pails that hung from the trees.

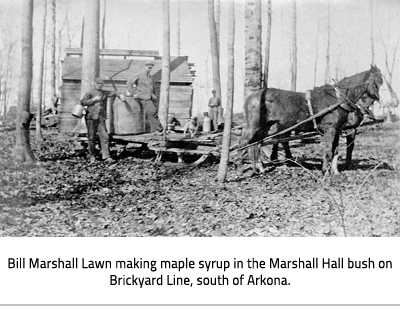

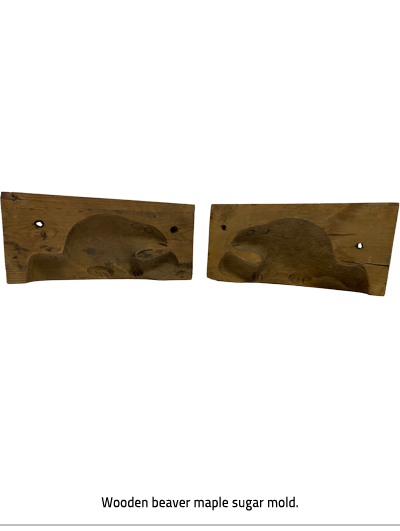

Sap is collected from the containers, combined, and boiled to remove excess water. The concentrated sap is heated until it reaches the temperature needed to make the desired product. Hot, thick maple sugar can be poured into a mold to create a solid shape. Further heating produces granulated sugar or maple syrup.

By the 1800s, the production and manufacture of maple products was an important social and economic activity for Indigenous peoples and settlers in the Great Lakes region. Syrup production remains an important annual activity in Lambton County. Many people have fond memories of visiting a sugarbush, learning how to make maple syrup, and sampling the sweet products.

Subscribe to this page

Subscribe to this page